Improving Coarse Coal Flotation by Enhancing Surface Hydrophobicity and Froth Stability Di Liu 1, Yongjun Peng, Sue Vink 2 1School of Chemical Engineering

Froth Flotation Cells are effective for the beneficiating of fine coal <, a process whereby fine coal can be separated from shale and other waste.

1 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of ...

The characteristic separation performance achievable from the treatment of fine coal using a froth flotation process is commonly estimated using either the release ...

Aggregate Flotation Process For Fine Coal ... This page is provide professional froth flotation of coal Froth flotation is a process for A Simplified Device for the ...

Coal preparation plants which clean ultrafine coal use the froth flotation process, ... EFFECT OF WATER QUALITY ON FROTH STABILITY IN FLOTATION Froth flotation .

chemical principles, is effective In recovery of fine coal. Conventional froth flotation techniques are not very effective for recovery of very

The froth flotation of ore and coal is significantly improved in recovery and grade of valuable minerals and coal when a depressant combination of an inorganic ...

froth flotation flow chart Coal processing system Machine for sale . Find the Right and the Top froth flotation flow chart for your coal handling plant!

Reduction of Sulfur and Ash from Tabas Coal by Froth Flotation ... In the conventional flotation process, ... hydrophilic effect to the coal surface than Methanol.

The amount and quality of concentrate obtained from froth flotation of a coal are very important to determine the efficiency of the separation process.

ABSTRACT Froth flotation is a universally accepted process for the beneficiation of coal fines. However, the process variables, collector dosage, frother dosage, and ...

A novel twostage froth flotation process to remove pyritic sulfur from finesize coal is described. The process consists of a firststage, standard coal flotation ...

While the reagent for froth flotation of bituminous coal has been shown and described in detail, ... Frothflotation process and product for effecting same: US *

Application of Froth Flotation Technique to Reduce Sulfur from Lakhra Coal Using Froth Flotation . Amir Shafeeq . 1, Mujtaba Ashraf . 2, Ayyaz Muhammad

The amount and quality of concentrate obtained from froth flotation of a coal are very important to determine the efficiency of the separation process.

Disclosed is an improved process wherein coal particles are beneficiated by froth flotation under coal froth flotation conditions to separate the desired coal ...

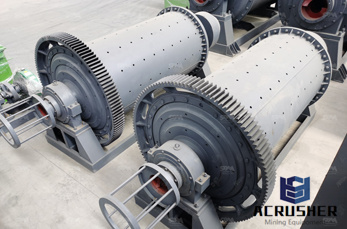

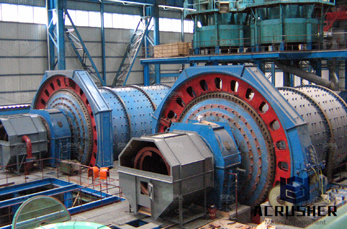

A paper presented discussing coal flotation with mechanical flotation machines and their setup / design for the best results. The reference is as follows;

Many Australian coal handling and preparation plants (CHPP) employ the froth flotation method to upgrade fine and ultrafine coal. Although coal and sulphide ore ...

B. Tech thesis on EFFECT OF KEY VARIABLES ON COAL CLEANING BY FROTH FLOTATION TECHNIQUE For partial fulfilment of the requirements for the degree of

Flotation of coal particles in MgCl 2 ... to hold the continuously produced froth during the flotation process. The froth height was recorded as a function of time at ...

coal density has great impact on froth flotation performance, but much ... Flotation process efficiency can be significantly enhanced by using

Eriez Column Flotation Cells Coal Industry. Eriez Column Flotation Cells are ideal for efficient high volume recovery of fine coal ( mm) particles.

The Froth flotation technique has not been widely applied industrially to separate processing of the ultrafine size fraction of coal. This is due to the low ...

WhatsApp)

WhatsApp)